How do the spots, stains, and other defects caused by alumina ceramics?

Alumina ceramics is a ceramic material with a-Al2O3 as the main crystalline phase. Due to its high melting point, high hardness, heat resistance, corrosion resistance, and electrical insulation characteristics, it can be used under harsher conditions.

The preparation of alumina ceramics will go through many production processes. During the process, there are more opportunities for materials to contact machinery, equipment, tools, utensils, and the environment. Therefore, there are more factors that cause pollution and porcelain quality problems. In general, the common color quality problems after alumina ceramics are fired are:

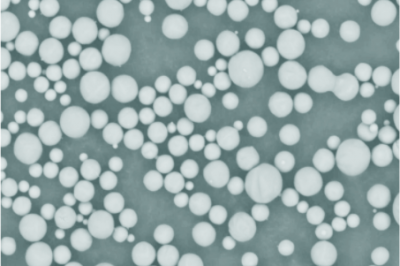

(1) There are spots on the surface of the porcelain piece, such as black spots, brown spots, and red spots;

(2) There are patches on the surface of the porcelain parts, such as dark spots (shade spots), black cloud spots, bright spots, etc.;

(3) Porcelain parts have color differences, such as overall yellowing or graying;

(4) Porcelain pieces are light yellow.

One, Spots

Pay attention to the following during compression molding:

(1) Raw materials: try to choose high-quality raw materials with low iron content, and perform magnetic separation to remove iron if necessary.

(2) Grinding: drop the bricks, pay attention to observe whether the lining bricks of the ball mill fall off, and repair them in time.

(3) Granulation: The slurry transportation is equipped with magnetic separation, iron removal, hot blast stove, and hot blast filtration to prevent rust from entering the material in the hot blast system. The granulated powder undergoes magnetic separation and iron removal before the final product is packaged.

(4) Piping: All pipelines should be lined with polyurethane as much as possible.

The use of lithium-ion batteries is becoming more and more popular, and the requirements for the performance of lithium-ion batteries are also increasing. As one of the key inner layer components of lithium-ion batteries, the performance of the separator determines the interface structure and internal resistance of the battery and directly affects the capacity, cycle,…

High filling: The thermally conductive material realizes heat conduction through phonons, and thermally conductive fillers play an important role in it. In order to improve the heat transfer efficiency of different thermal conduction channels, powders of different particle sizes are usually used to achieve close filling between particles, to obtain a mixture with low viscosity…