The key to the environmentally friendly flame retardant treatment method is which treatment method is used to add the flame retardant to the wooden material and how to increase the flame retardant performance of the flame retardant while improving the penetration of the flame retardant liquid of the wood used. At present, two widely used treatment methods are spray treatment and dipping treatment.

Surface spray treatment refers to painting or spraying flame retardant or flame-retardant coating on the surface of post-processed wood and its products to isolate the heat source, prevent the material's surface from contacting air, and reduce the combustion performance. It is suitable for wood materials that do not require high flame retardancy or wood materials that are inconvenient for immersion treatment, such as ancient building wood components.

The advantage of spraying treatment is that it can effectively control the spread of the fire; the dosage is small. The physical and mechanical properties of the wood are less affected; the flame retardant has good resistance to loss, the process is simple. And the disadvantage is that it covers the original texture and texture of the wood. Once the protective layer is damaged, its flame-retardant properties disappear immediately.

At present, the mainstream varieties of environmentally friendly flame retardants are all water-solvent products, so the addition method is immersion treatment. The impregnation treatment is a flame retardant treatment method. The flame retardant solution is injected into the wood or wood-based panel under normal pressure, vacuum, pressurization, or extensive use of several pressure conditions. The impregnation treatment in the flame-retardant treatment method of wood materials, especially the high-pressure impregnation method, is widely used in production and has sound flame-retardant effects.

The use of lithium-ion batteries is becoming more and more popular, and the requirements for the performance of lithium-ion batteries are also increasing. As one of the key inner layer components of lithium-ion batteries, the performance of the separator determines the interface structure and internal resistance of the battery and directly affects the capacity, cycle,…

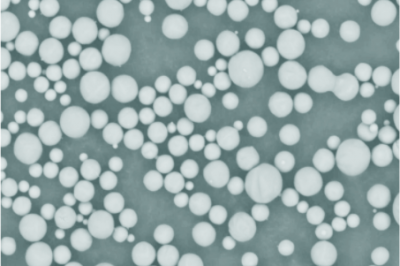

High filling: The thermally conductive material realizes heat conduction through phonons, and thermally conductive fillers play an important role in it. In order to improve the heat transfer efficiency of different thermal conduction channels, powders of different particle sizes are usually used to achieve close filling between particles, to obtain a mixture with low viscosity…