Luoyang Zhongchao New Materials Co., Ltd. (hereinafter referred to as ZC-TECH), is a high-tech enterprise specializing in the production of ultra-fine aluminum hydroxide flame-retardant materials. In 2020, the sales volume of ultra-fine aluminum hydroxide flame-retardant materials exceed 140,000 tons. The company takes "Never-Stop, Pursuit of Excellence" as its core philosophy, and constantly creates new value for every client!

ZC-Tech based on the deep technology accumulation of self-manufacturing powder, the company uses the advantages of the company’s raw materials and adopts advanced production technology to produce special alumina powder and boehmite powder with high purity, concentrated particle size distribution, good dispersion, and batch The advantages of good stability, etc., can be widely used in the field of lithium battery separator coating, which can significantly improve the safety of lithium batteries.

product description:

Special alumina: Nano alumina is an inorganic substance with a chemical formula of Al2O3, white crystalline powder, with various crystals such as α, β, γ, δ, η, θ, κ and χ. The crystal form of the special alumina coated on the lithium battery diaphragm is α phase, and the crystal structure is similar to spherical.

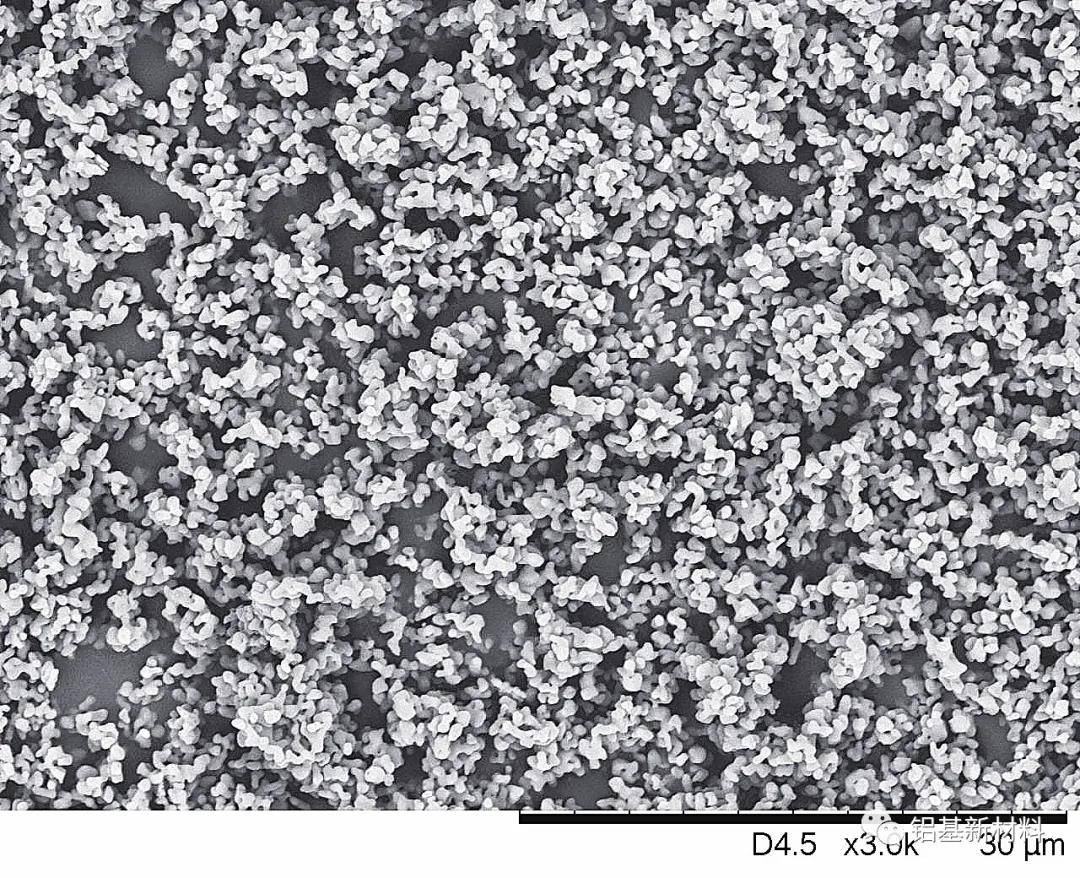

Scanning electron microscope image of special alumina of ZC-TECH.

Scanning electron microscope image of special alumina of ZC-TECH.

Product characteristics: diaphragm ceramic coating use

(1) The coating film has a low moisture content

(2) The powder is easy to disperse, and the ceramic slurry has good stability

(3) After coating, the increase in air permeability is small, and the heat shrinkage is small

(4) Concentrated particle size distribution and moderate hardness

(5) Good batch stability

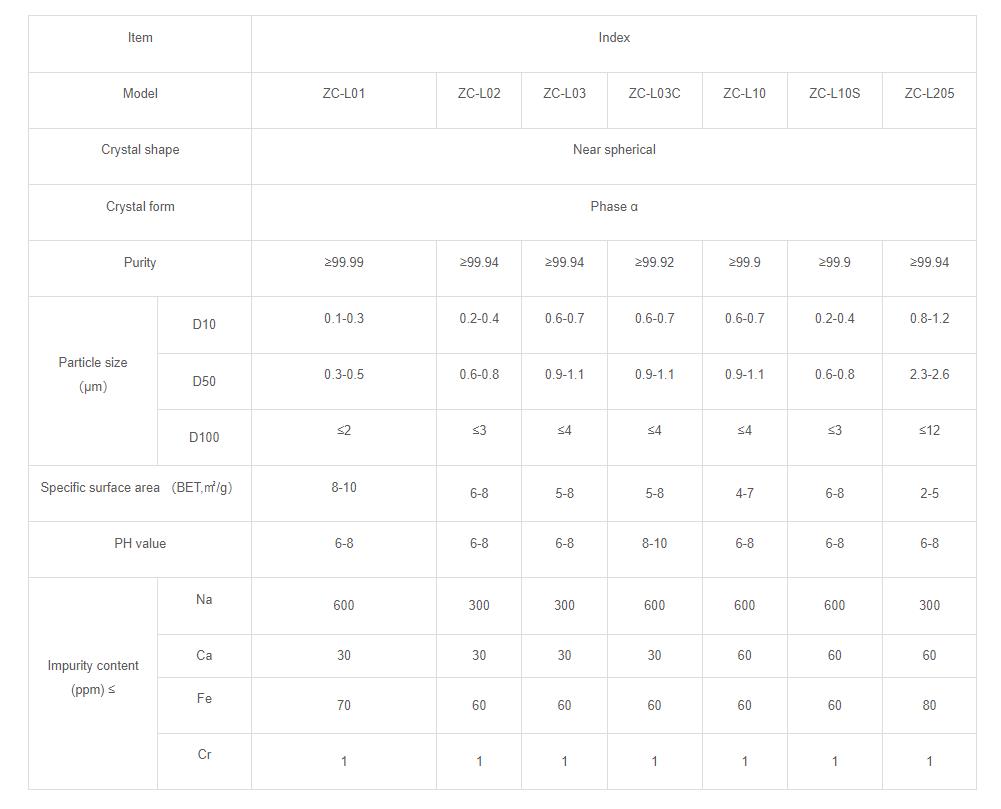

Product index:

Luoyang Zhongchao Co., Ltd. Nano alumina product technical indicators

The influence of ceramic coating separator on the performance of lithium-ion battery:

Using polyethylene (PE) diaphragm for the lithium-ion battery as the matrix, the uniform coating thickness is 1-2μm on both sides of the inorganic and organic slurry mixed with special alumina (Al2O3) powder and gelling agent to obtain an inorganic Composite ceramic coating lithium-ion battery separator.

The results of the hot oven test on battery separators and batteries made of such separators show that the inorganic ceramic coating separator does not show large thermal shrinkage under a high-temperature environment of 150 ℃, has superior stability, and can effectively improve lithium Thermal safety of ion batteries. Because the inorganic nano Al2O3 has a higher specific surface area, the coated diaphragm has good wettability and liquid retention performance to the electrolyte. A battery assembled with a ceramic-coated separator was subjected to a charge-discharge cycle test, and the results showed that the coated separator can effectively improve the capacity retention performance of the lithium-ion battery.

Boehmite (γ-AlOOH) is the main component of bauxite, and It is an important chemical raw material with a unique crystal structure. It is widely used in many fields such as catalysts and carriers, paper fillers, inorganic flame retardants, etc. In particular, it can be used as a precursor to prepare aluminum oxide, which is widely…

What is a ceramic setter plate? In layman’s terms, a ceramic setter plate is a tool used in the ceramic kiln to carry and transport the burned ceramic green body. At present, the sintering temperature of composite setter used for setter MLCC is generally above 1200℃, requiring higher ceramic setter plate requirements. Domestic materials typically…